Sequencing Batch Reactor Manufacturer

Sequencing Batch Reactor

The SBR is designed for high-performance sewage treatment solution that combines the advantages of batch and continuous flow. This high-performance and versatile technology is suitable for the most stringent discharge standards and provides stable performance despite any flow variations. This high-quality product generates minimal operating costs and is easy to maintain & modify.

THE TECHNOLOGY HIGHLIGHTS

Treatment of high load municipal or industrial wastewater and treatment in warm or cold climates Optimizing operating and equipment costs through a streamlined design

Upgrading conventional treatment systems simply and at a minimum cost Meeting requirements respecting effluents, regardless of the prevailing conditions Basic SBR cycle comprises filling with aeration, settling of sludge and decanting.

Completion of the sequences described above constitute a cycle which is then repeated. During the period of a cycle, the liquid volume inside the vessel increases from a set minimum operating bottom water level in response to a varying influent flow rate.

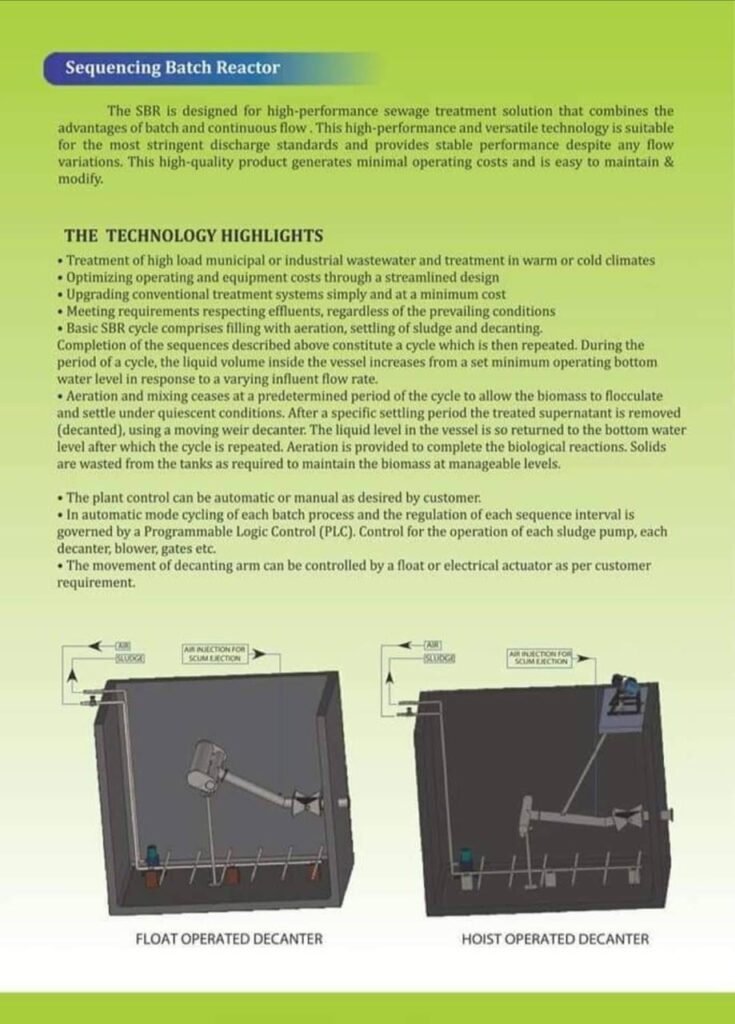

Aeration and mixing ceases at a predetermined period of the cycle to allow the biomass to flocculate and settle under quiescent conditions. After a specific settling period the treated supernatant is removed (decanted), using a moving weir decanter. The liquid level in the vessel is so returned to the bottom water level after which the cycle is repeated. Aeration is provided to complete the biological reactions. Solids are wasted from the tanks as required to maintain the biomass at manageable levels.

The plant control can be automatic or manual as desired by customer.

In automatic mode cycling of each batch process and the regulation of each sequence interval is governed by a Programmable Logic Control (PLC). Control for the operation of each sludge pump, each. decanter, blower, gates etc.

The movement of decanting arm can be controlled by a float or electrical actuator as per customer requirement.